UPCOMING EVENTS

Bio4Energy Researchers’ Meeting

2024-06-03This is where Bio4Energy’s researchers and students meet and greet. The conference sessions will be held at the premises of RISE Processum and a study visit to RISE Bioeconomy Arena will be organised. Attendance is by invitation. We look forward to seeing you! Here are your links to the Meeting programme and Registration. Please register […]

Biorefinery Pilot Research, Bio4Energy Graduate School

2024-09-02Bio4Energy’s flagship training on location in industry that develops biorefinery production along the East coast of northern Sweden. Opening of the application for the 2024 edition is planned for May. New for April 2024: Course Brochure Biorefinery Pilot Research

Bio4Energy Advisory Board Meeting

2024-09-02On site event at RISE Bioeconomy Arena, Sweden’s new development park in northern Sweden.

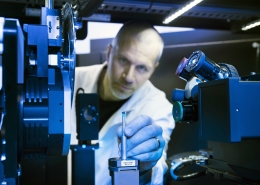

IO ANTONOPOULOU, Bio4Energy Biopolymers and Biochemical Conversion

Biochemical Process Engineering

Luleå University of Technology

“Bio4Energy has allowed me to develop new research lines within the field of energy and CO2 sequestration. In the Bio4Energy research environment, I had the opportunity to meet with excellent researchers for building new collaborations”.

©AnnaStrom

©AnnaStrom ©AnnaStrom

©AnnaStrom Bio4Energy

Bio4Energy

Dreamstime

Dreamstime ©AnnaStrom

©AnnaStrom

AnnaStrom

AnnaStrom